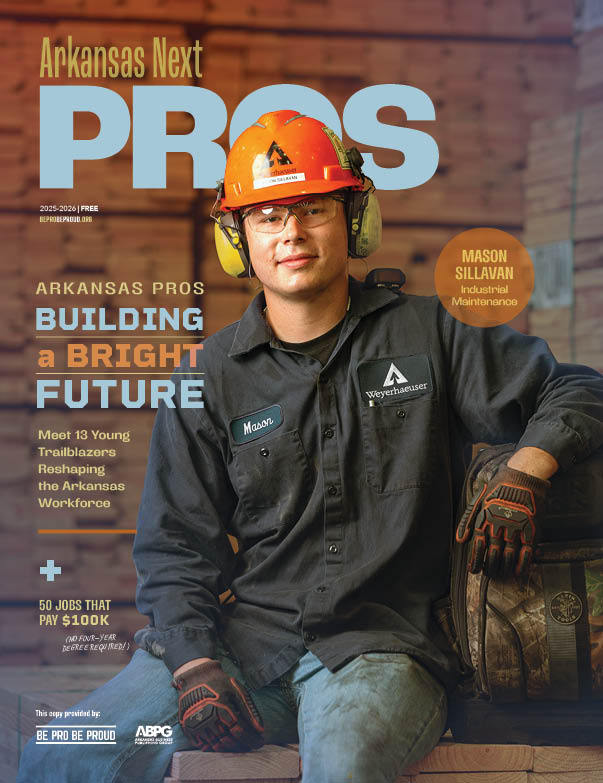

MEET THE PRO: Billy Gentry, Manufacturing Technician

By Arkansas Next on Monday, October 25, 2021

Hometown: Magnolia

Age: 28

Where I trained: University of Arkansas Hope–Texarkana and Southern Arkansas University Tech

What I earned: Associate degree of industrial science and technology and an associate degree of engineering electrical and a technical certificate

Job title: Manufacturing technician

Employer: Aerojet Rocketdyne

Billy Gentry served in the U.S. Army and watched rockets in action while on active duty. After finishing his service, he decided that helping build those same rockets would be a way to still help his brothers in arms and defend his country.

Billy likes his job in Aerojet Rocketdyne’s Manufacturing Engineering/Rocket Test Division because he likes the challenge of instrumentation and testing rocket motors in many different environments. "Whether it is hot, cold, or raining, we still test motors. The difficulty of testing in a specific timeframe, all while being monitored, is sometimes stressful. Sometimes our hands have to work in tight or small spaces, and special tools may be required to complete the job accurately."

Billy prefers the hands-on nature of his work and likes that with this job he can work a full-time job and still go to school. He feels like this route has led him to his promotions, and he is already taking the lead on instrumentation of motors. He hopes to eventually take more of a lead in the control room, too.

"I like the instrumentation process and working to get the motors ready for testing. A successful test means we are giving our soldiers the best quality product which allows them to perform their job safely and get the job done!" – Billy

WHAT DOES A MANUFACTURING TECHNICIAN DO?

A manufacturing technician performs critical time sensitive functions. Some of these duties include installing instrumentation, like strain gauges, thermal sensors and accelerometers on the motor prior to testing. Other duties include assisting in the function of the live motor while on the test stand.

Responsibilities

- Making safety the No. 1 priority

- Ensuring all tools and equipment used are well maintained and functioning properly

- Ensuring instrumentation kits are built to standard and are ready for use

- Calibrating load cell and pressure transducers for test

- Testing motors within the time allotted

Education needed: Associate degree or two years of equivalent experiences or military background

Job Outlook

► 12% expected growth by 2028 in Arkansas

► 6,970 jobs by 2028 in Arkansas

► 840 average annual job openings in Arkansas

This option is for you if

- You’ve got an eye for the details

- You follow directions

- You thrive under pressure

- You are great at communication

- You think outside the box

High-end earners (top 10%) make

$62,260

Median wages in Arkansas

$42,470 Annual

$20.42 Hourly

MACHINING PROFESSIONS

START YOUR TRAINING

• Arkansas State University–Beebe

• Arkansas State University–Mid-South

• Arkansas State University-Mountain Home

• Arkansas State University–Newport

• Phillips Community College of the University of Arkansas

• Simmons Foods

• Tyson Foods Inc.

• University of Arkansas Hope–Texarkana

• University of Arkansas–Pulaski Technical College

READY TO HIRE YOU

• Central Moloney Inc.

• Hytrol

• McKee Foods Corporation

• Pace Industries

• Simmons Foods

• Tyson Foods Inc.

OPERATING TECH / OPERATOR PROFESSIONS

START YOUR TRAINING

• Arkansas Construction Education Foundation

• Arkansas Electric Cooperative Corporation

• Phillips Community College of the University of Arkansas

• Simmons Foods

• Tyson Foods Inc.

• University of Arkansas Hope–Texarkana

READY TO HIRE YOU

• Arkansas Electric Cooperative Corporation

• Central Moloney Inc.

• McGeorge Contracting Company

• OK Foods

• Pace Industries

• Simmons Foods

• Tyson Foods Inc.

Sources: bls.gov and careeronestop.org