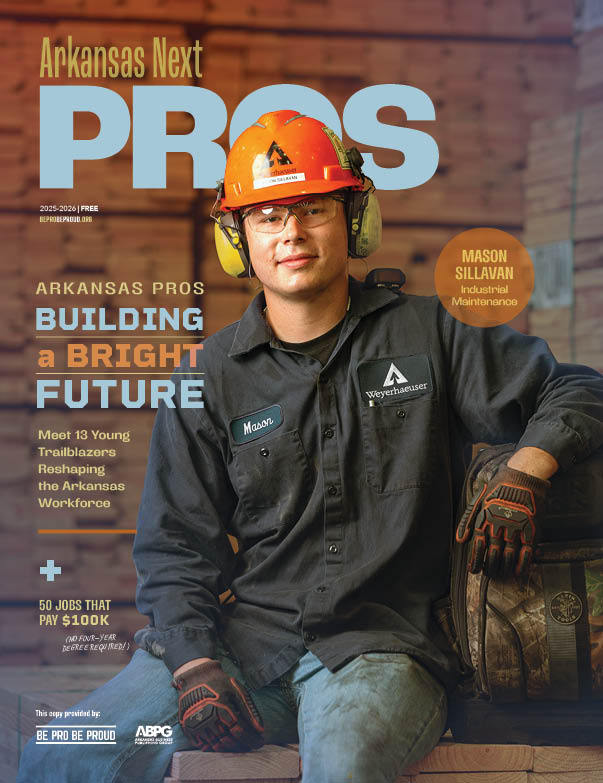

MEET THE PRO: Sean McGuffey, Tool & Die Maker

By Arkansas NEXT on Friday, September 25, 2020

Sean McGuffey

Hometown: Fort Worth, Texas

Age: 31

Where I trained: On-the-job training at Class A Tooling in Cabot

What I earned: High school diploma and MasterCam University Certificate

Job title: Lead Tool Maker

Employer: Central Moloney Inc. in Pine Bluff

Sean McGuffey had worked in the tool and die making industry for four years before deciding to take a job with Central Moloney. “Within the industry, there are different specializations, and moving here has allowed me to be more involved in building molds,” he says. Sean learned the tool and die trade via on-the-job training, but he recommends paying attention in trigonometry class. “I started out knowing nothing about it, and the knowledge I've gained over the past 13 years has made me lead toolmaker,” he says.

A boring, desk-job life just wasn’t right for Sean. “I get to work with my hands and create a finished product,” he says. “I get to hold the accomplishments of my hard work in my hands.”

Looking toward the future, Sean hopes to one day become a tool designer. “I already design some of my own toolings, and I really enjoy it,” he says. “I would love to be the designer for all of the tools.”

What does a tool and die maker do?

Tool and die makers are a class of machinists in the manufacturing industry. These pros primarily work in toolroom environments. They are skilled artisans who typically learn their trade through a combination of coursework and hands-on experience, with quite a bit of on-the-job training. They make jigs, fixtures, dies, molds, machine tools, cutting tools, gauges and other tools used in manufacturing processes.

Responsibilities

► Build tools from start to finish.

► Program CNC machines.

► Measure and calculate dimensions of completed products or equipment.

► Review blueprints or other instructions to determine operational methods or sequences.

► Operate grinding equipment.

► Operate metal or plastic forming equipment.

Related Occupations

Patternmakers (wood, metal and plastic), machinists, model makers (metal and plastic), drilling and boring machine tool setters

What’s the Difference? Tool & Die vs. Machinist

Similarities

Machinists and tool and die makers set-up and operate a variety of computer-controlled and mechanically controlled machine tools to produce precision metal parts, instruments and tools.

Differences

Tool & Die Makers

► Construct precision tools or metal forms, called dies, that are used to cut, shape, and form metal and other materials.

► Use computer-aided design (CAD) to develop products and parts.

► Often make many parts and assemble and adjust machines used in the process.

Machinists

► Use machine tools, such as lathes, milling machines, and grinders, to produce precision metal parts.

► Either use manual or computer numerical control machinery (CNC) to create products and parts.

► Normally make a single part during the production process.

Education Needed

Tool and die makers should have a certificate or associate degree, and long-term on-the-job-training.

Machinists typically have a high school diploma or equivalent, whereas tool and die makers may need to complete courses beyond high school. Some community colleges and technical schools have two-year programs that train students to become machinists or tool and die makers. These programs usually teach design and blueprint reading, the use of a variety of welding and cutting tools, and the programming and function of CNC machines.

Job Outlook

6,700

projected annual job openings in the U.S.

TOOL & DIE MAKERS

High-end earners in Arkansas (top 10%) make

$61,350 Annually

Median wages in Arkansas

$44,490 Annually

$21.39 Hourly

MEDIAN ANNUAL U.S. WAGES

Tool & Die Makers

$53,920 Annually

Machinists

$44,420 Annually

This option is for you if:

► You have a knack for thinking outside of the box.

► You’re good at time management.

► You pay attention to detail.

► You’re good with numbers.

► You’re willing to continuously learn.

START YOUR TRAINING

| Arkansas State University - Beebe (Searcy campus) | T&D |

| North Arkansas College | T&D |

| Arkansas Tech University - Ozark Campus | Mach. |

| Southern Arkansas University Tech | Mach. |

READY TO HIRE YOU

| Central Moloney Inc. | T&D, Mach. |

| Hytrol | T&D, Mach. |

| Tyson Foods | T&D |

| Haas Factory Outlet, a Division of Phillips | Mach. |

"I like that I get to figure out new ways to make something work. Everything in the tooling world is so precise, which means that it can be hard to make an idea work, but when it does come together, it's a great feeling. I really enjoy the challenge." –Sean

Sources: U.S. Bureau of Labor Statistics, BLS.gov, CareerOneStop.org and CollegeGrad.com